The need to identify both the polymer (or polymers) that constitute a product and the presence of additives, modifiers and inorganic fillers is very frequent.

Superlab, with the aid of reliable laboratory techniques and through consultation of its database, established on the basis of selected reference products of an original chemical nature (“reference markers”), can perform diagnostic analyzes and provide information on the nature and the composition of plastic products and products, identifying polymers, modifiers and auxiliaries in combination with each other.

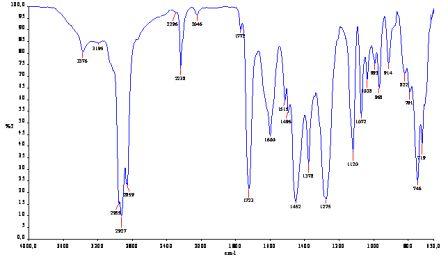

INFRARED SPECTROSCOPY (FT/IR)

This technique, which allows us to recognize the chemical nature of polymers, fillers and various additives, is used to identify the components of thermoplastic and thermosetting polymeric materials and rubbers and to verify the presence of any pollution.

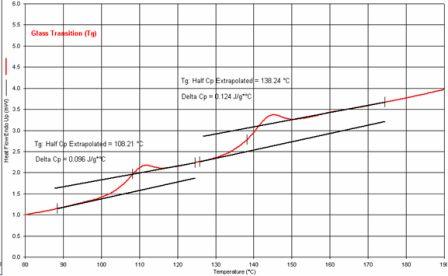

DIFFERENTIAL SCANNING CALORIMETRY (DSC) WITH LOW TEMPERATURE OPTION (Scanning starts from –80 °C)

It is a sophisticated technique that allows you to identify the polymer/components of the sample under examination and to study the degree of crystallinity of the polymeric materials.

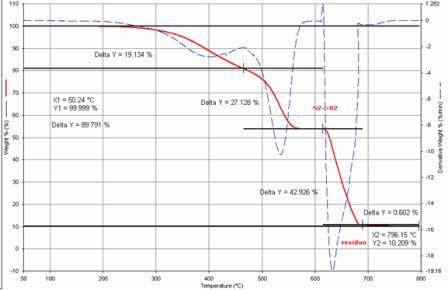

THERMOGRAVIMETRY (TGA)

The recorded degradation kinetics allows to evaluate the thermal stability of the polymer components and the presence of inert materials in the polymer itself.

SOLVENT EXTRACTION

This evaluation allows any components to be extracted from a polymer by exposing samples to appropriate solvents for different times and temperatures depending on what is being examined.

CALCINATION IN THE MUFFLE

The measurement of the ash content, by calcination in a muffle, makes known the quality of inert material (mineral fillers, glass fibres, pigments, etc.) contained in a given polymer.

It occurs by destroying the polymer in the furnace at a well-defined temperature and time.

“POLYMERS & COMPOSITES”

The educational contribution that cannot be missing in the daily practice of professionals who in various capacities operate in the plastics sector.

The work tells about the world of polymers, the way of producing them and qualifying them, with the ambition of encouraging the development of applications according to the expected performance expectations.

You can learn how to intervene on polymer matrices to adapt them to transformation technologies, with the aim of obtaining qualitatively and commercially competitive products, imposing adequate attention to the effects on the environment in the formulation interventions, while trying at the same time to transfer knowledge and affection for polymeric materials.