SUPERLAB EQUIPMENT

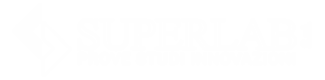

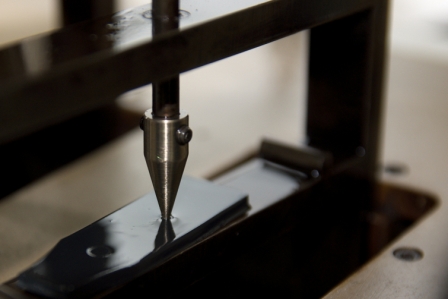

VICAT softening temperature according to ISO 306 – ASTM D 1525

This characterization provides an indication of the temperature at which a plastic material begins to soften rapidly.

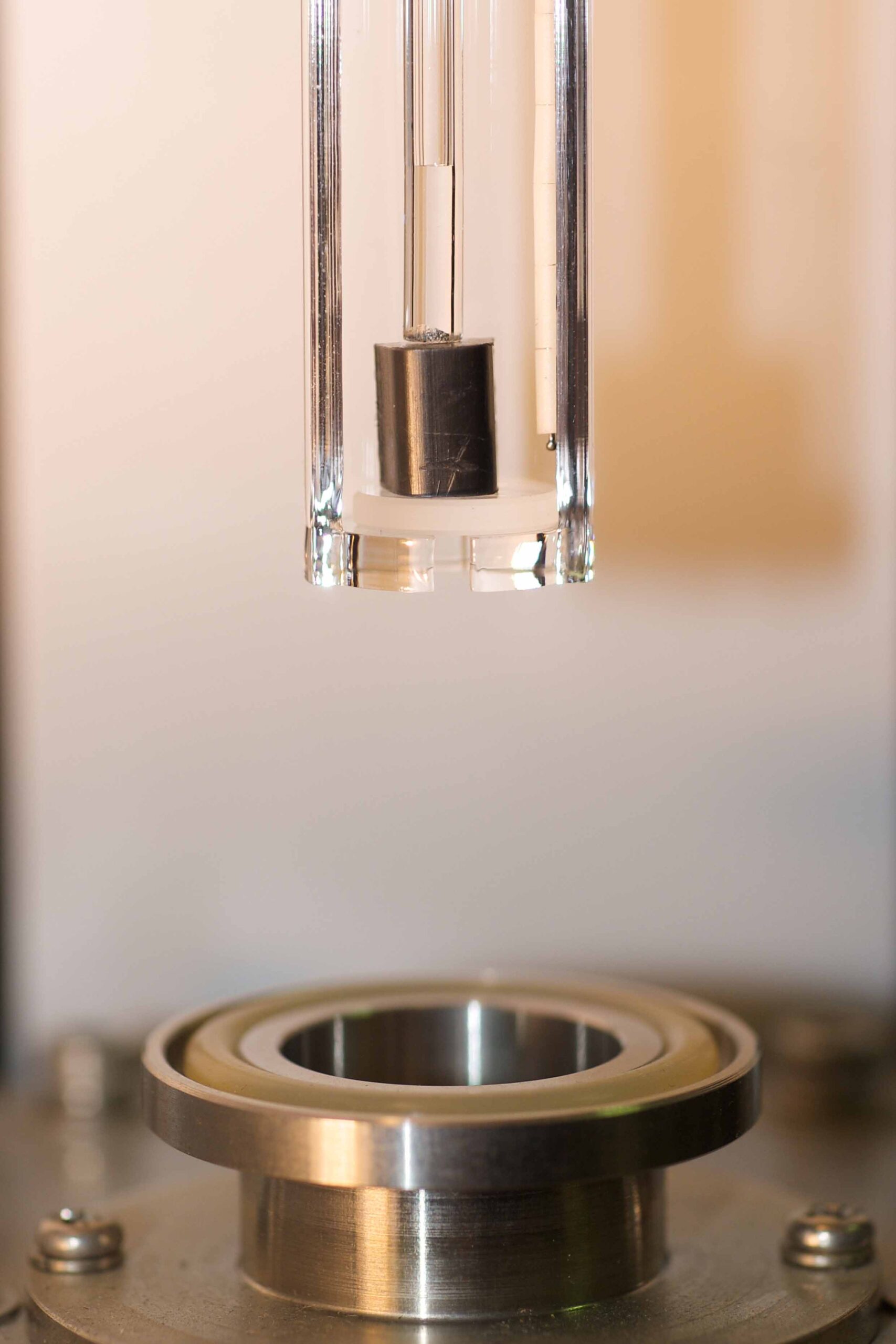

DISTORTION TEMPERATURE UNDER LOAD (HDT OR DTUL)

Distortion temperature under load (HDT or DTUL) according to ISO 75 – ASTM D 648

This measurement highlights the ability of a material to retain its characteristics for short periods of time under load at high temperatures.

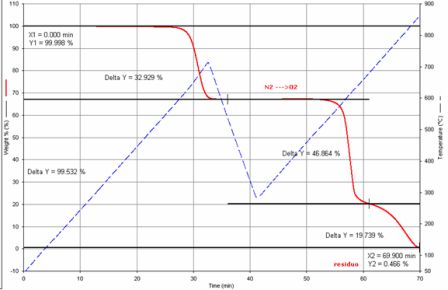

THERMOGRAVIMETRY (TGA)

Thermogravimetry (TGA) according to ISO 11358

Using thermogravimetry (TGA), the weight loss due to degradation of a polymer sample subjected to an increase in temperature is recorded.DIFFERENTIAL SCANNING CALORIMETRY (DSC)

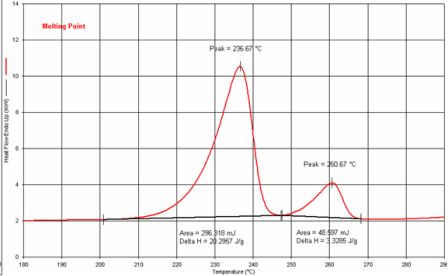

Differential Scanning Calorimetry (DSC) according to ISO 11357.

It is a sophisticated technique that allows you to identify the polymer/components of the sample under examination and to study the degree of crystallinity of polymeric materials.O.I.T. OXIDATIVE INDUCTION TIME

O.I.T. Oxidative induction time, according to ISO 11357.

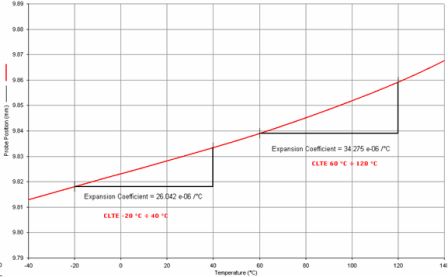

This is a sophisticated technique that allows the technical stability of polymers to be assessed.C.L.T.E LINEAR THERMAL COEFFICIENT OF EXPANSION

Linear thermal expansion coefficient according to ISO 11359 – ASTM E 831.

This is a sophisticated technique that allows you to measure the variation in length of a material subjected to thermal scanning.GLOW WIRE TEST

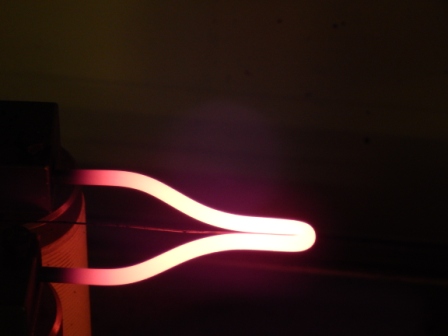

Glow Wire Test –GWT according to IEC 60695

This measurement, which the standard states can be carried out both on specimens and on parts of manufactured goods, reproduces the thermal stresses produced by heat sources or ignition sources corresponding to incandescent elements and/or parts of electrical components due to voltage overloads.FLAME RESISTANCE

Flame resistance according to UL94

The evaluation of this property according to the UL94 standard and classifications represents the standard for most users.

This evaluation is intended to provide a preliminary indication of the flammability of plastic materials when standard-sized specimens are subjected to heating and flame application under controlled laboratory conditions.THERMAL AGING

Thermal aging in an air circulation oven.

Thermal ageing, by exposing specimens and/or artefacts in an air circulation oven, is often used to accelerate the aging process and it is possible to evaluate phenomena of aesthetic and performance degradation in a limited time.

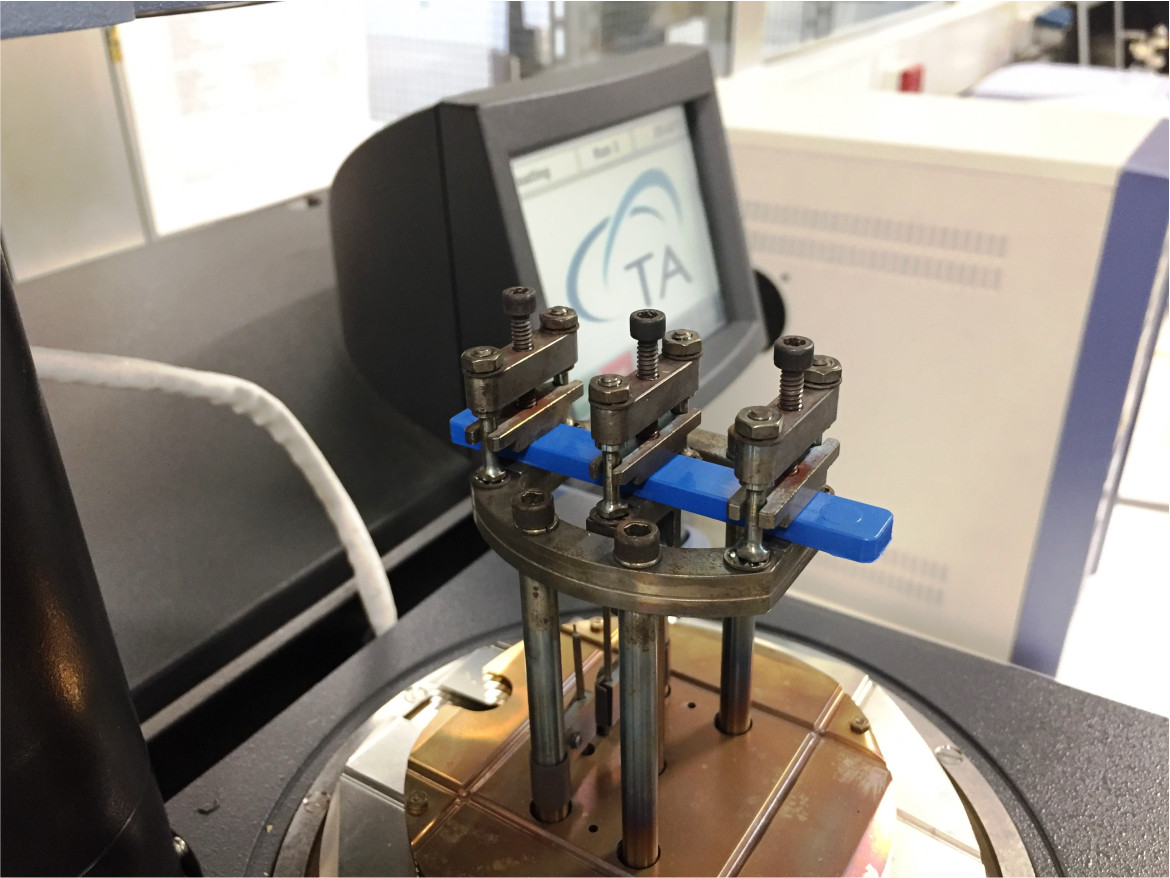

DMA DYNAMIC MECHANICAL ANALYSIS

Dynamic mechanical analysis (DMA) measures the viscoelastic properties of most polymeric and composite materials during a program of increasing temperature and constant or variable frequency.

“POLYMERS & COMPOSITES”

The educational contribution that cannot be missing in the daily practice of professionals who in various capacities operate in the plastics sector.

The work tells about the world of polymers, the way of producing them and qualifying them, with the ambition of encouraging the development of applications according to the expected performance expectations.

You can learn how to intervene on polymer matrices to adapt them to transformation technologies, with the aim of obtaining qualitatively and commercially competitive products, imposing adequate attention to the effects on the environment in the formulation interventions, while trying at the same time to transfer knowledge and affection for polymeric materials.